Hirayama Gemba Kaizen Consulting ABOUT US

Based on TPS (Toyota Production System), we will thoroughly eliminate waste and provide guidance support for creating your own production system in order to realize your management strategy.

We analyze the current situation and review the direction of reform. While educating employees, we will provide guidance and support that is suitable for your company’s shop floor, and will realize “improvement of quality, cost competitiveness, and performance” and “human resource development”.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

GEMBA KAIZEN

Service List

SERVICE

Upcoming

Seminars / Training

SEMINAR/TRAINING

There are no scheduled events scheduled.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

3 reasons why we are chosen REASON

REASON 1

Improvement experience of

more than 1,500 companies in 40 countries

There must be the shop floor issues that cannot be solved by your own company alone. Improvements and reforms for manufacturing industry to survive, regardless of country or industry, need development of your human resources through practical experiences of improvement, and strengthening of your production system base.

REASON 2

Consulting that shop floor workers

acknowledge our superiority and be pleased

In conventional consulting styles, there was a distance between consultant and the shop floor because it was promoted mainly consultant and management executives. Our consultant can provide a guidance without a distance between consultant and the shop floor through the guidance based on the “seeds of improvement” in a concrete way, instead of “finding fault” like a critic.

REASON 3

Continuous improvement will continue

even after the end of guidance

While strengthening “human resource development”, we focus on the “overall flow” from design to purchasing, manufacturing, logistics, and production control, and provide guidance that matches the actual situation of your company. Continuous improvement will continue even after the end of guidance through the guidance that is acceptable to the shop floor workers.

Consultants strong

in Gemba Kaizen

CONSULTANT

The consultants are all experienced personnel who have accumulated many achievements at the shop floor of major manufacturing companies.

There are many consultants who have TPS trainer qualifications, and our practical and accurate consulting is highly evaluated both in Japan and overseas.

Former Chief Leader of Headquarter plant, Toyota Motor Corporation (OB)

Former employee of Sony Corporation (OB)

Former deputy plant manager of Tahara plant, Toyota Motor Corporation (OB)

Manager of Consulting Division

Actual introduction effects of

HIRAYAMA CONSULTING BUSINESS

CASE STUDY

[Case Study] Productivity Improvement Project at an Overseas Factory

- Shortening of Lead Time

- Inventory Optimization

- Reduction of Transport (Handling) Distance

- Productivity Improvement

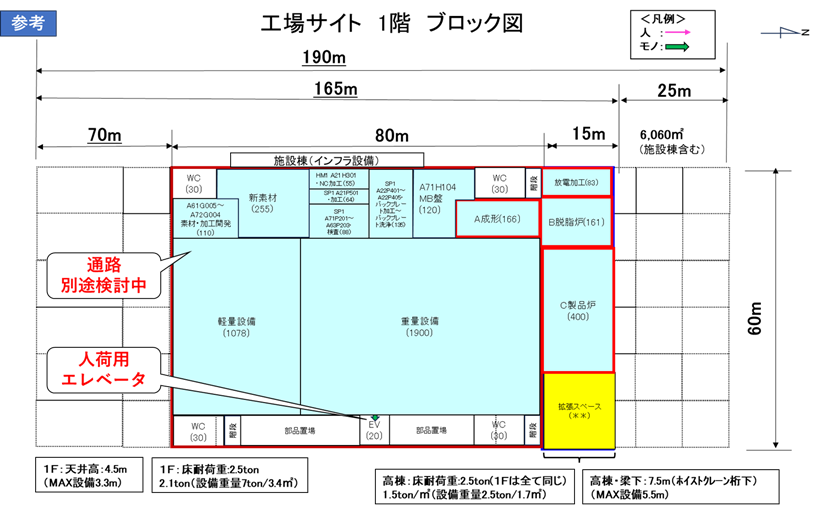

Case Study: Improvement of a New Factory Layout

Establishing a New Plant to Increase Production Capacity by 40%

What's new NEWS

- 2025/12/24

- Year-End and New Year’s Greetings

- 2025/11/27

- TPS Seminars Anytime, Anywhere

- 2025/06/13

- [Case Study] Eliminating 12 Types of Muda – Workshop Seminar

- 2025/04/23

- 【In Response to Your Inquiry】Embedding TPS and Kaizen Practices

- 2025/01/10

- Training for Enhancing Production Site Capabilities at a Factory in Vietnam