Remote Genba Kaizen (shop floor improvement) service is a service that an experienced shop floor improvement consultant remotely diagnoses and improves the manufacturing shop floor using internet communication.

For example, managers and operators wear cameras, earphones, and microphones, and its video and audio data is sent to the consultant in Japan, and the consultant gives instructions for work improvement etc. directly through the internet communication.

Solve these issues

with Remote Genba Kaizen service

ISSUE

3 points

for Remote Genba Kaizen service

FEATURES

-

1

Real-time problem finding

-

Immediate consulting when a problem occurs with real-time video and audio.

-

2

Improvement results in a short period of time

-

Gaining improvement results in a short period of time by consulting provided only when needed and for the time needed.

-

3

Great effect at low cost

-

Online implementation solves the problem of trasnportation and accommodation costs of consultants. You can expect great effect at low cost.

Real-time problem finding

Real-time video and audio do not make you feel distant. In the same way as actually going to the shop floor, a factory diagnosis is performed in real time using on-site video and audio.

It also allows us to provide immediate consulting services when a problem occurs.

Improvement results in a short period of time

Genba Kaizen consulting, which was once a month due to travel distance and transportation cost issues, can be conducted several times a month.

It is possible to provide the Genba Kaizen consulting closer to a person in charge of improvement and operators, and also possible to immediately check the improvement results visually, so you can expect the improve activities and results in a shorter time than usual.

Great effect at low cost

Devices for the remote shop floor improvement consulting, such as a camera with built-in glasses in the same size as actual glasses or a helmet-type camera, is compact and easy to operate.

In addition, it can save time and costs such as travel distance and transportation cost of consultants, so it is lower cost than ordinary consulting. The range of improvement can be expanded, and a great effect is possible.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Remote Genba Kaizen Specialist

KAKIZAWA, Kouichi

Ricoh Co.

Implemented TPS and Kaizen in food product companies and medical devices companies. Quality control improvement, Shojinka, Production improvement, Cost reduction are his area of specialty.

Case example of Genba Kaizen Consulting RESULTS

Acquired orders from two new customers

by improving quality.

We reduced most work-in-progress inventories and defective inventories, which were found throughout the factory, and reduced manpower, and now we almost no longer receive customer complaints that we had every month before. (Automobile industry / Plant manager)

Turn the factory into a showroom

in order to improve profitability

We improved 250 cases out of 300 cases pointed out by the 5S patrol conducted for one year. The factory was realized to be the showroom and also achieved cost reduction of 30 million yen per year. (Metal processing / Director)

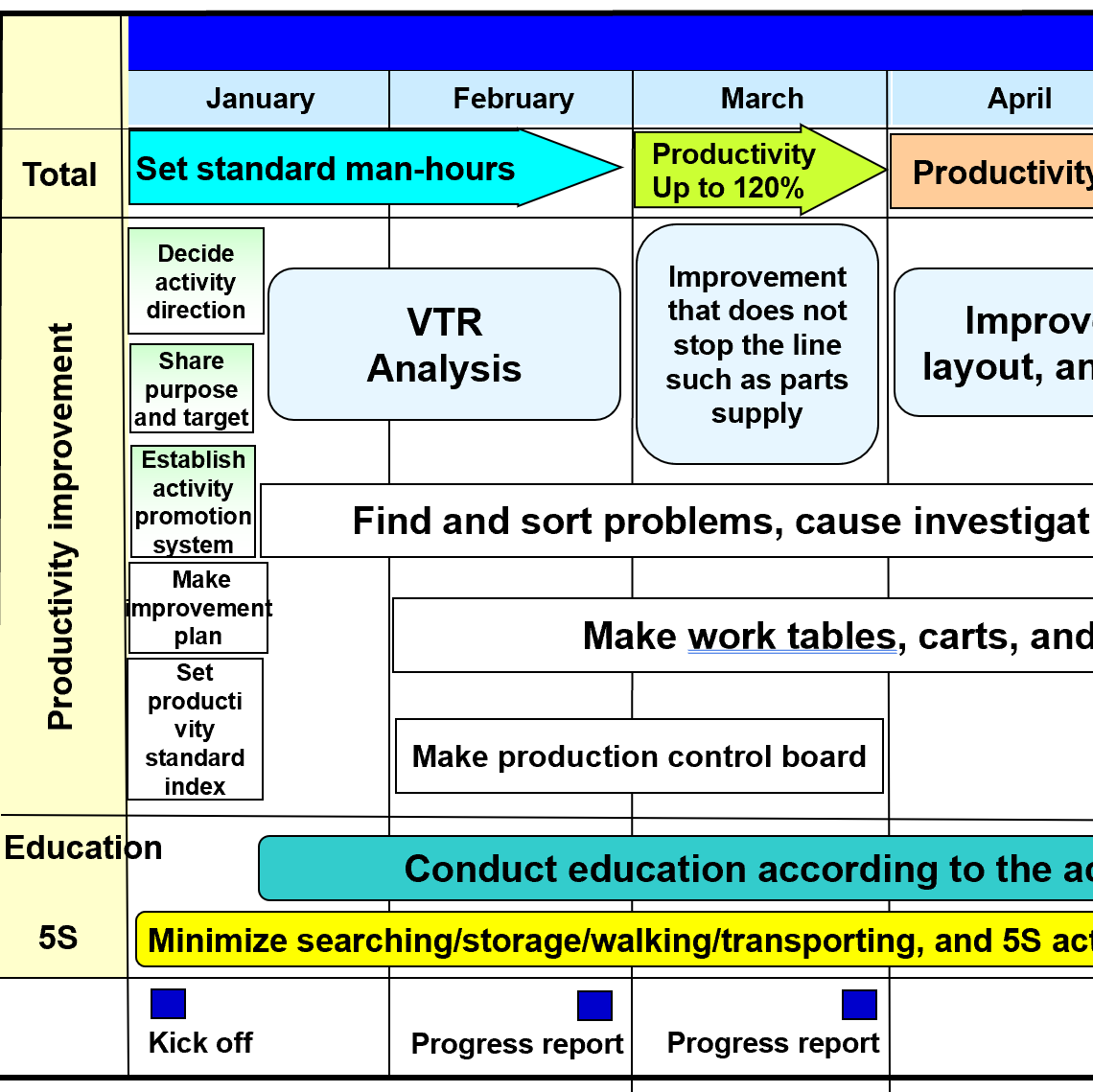

Productivity Up to 169.6%

by 6 months of improvement activities

the Japanese president decided to outsource a shop floor improvement consulting to have their shop floor checked, and asked us, Hirayama Consulting.(Auto parts manufacturer/Managing director)

3 reasons why we are chosen REASON

REASON 1

Improvement experience of

more than 1,500 companies in 40 countries

There must be the shop floor issues that cannot be solved by your own company alone. Improvements and reforms for manufacturing industry to survive, regardless of country or industry, need development of your human resources through practical experiences of improvement, and strengthening of your production system base.

REASON 2

Consulting that shop floor workers

acknowledge our superiority and be pleased

In conventional consulting styles, there was a distance between consultant and the shop floor because it was promoted mainly consultant and management executives. Our consultant can provide a guidance without a distance between consultant and the shop floor through the guidance based on the "seeds of improvement" in a concrete way, instead of "finding fault" like a critic.

REASON 3

Continuous improvement will continue

even after the end of guidance

While strengthening "human resource development", we focus on the "overall flow" from design to purchasing, manufacturing, logistics, and production control, and provide guidance that matches the actual situation of your company. Continuous improvement will continue even after the end of guidance through the guidance that is acceptable to the shop floor workers.