Key Points for the Construction, Expansion, and Renovation of New Factories

In factory setup support, we assist with the construction of new factories, expansion of existing factories, and renovation of used factories.

Consultants with experience in factory construction both domestically and internationally will help build highly efficient production lines and support your problem-solving needs.

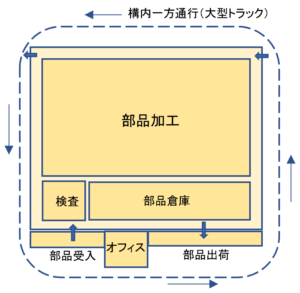

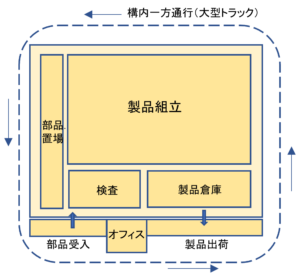

Examples of Factory Layouts

While individual cases may vary, a basic approach for a parts factory might include creating a flow from material receiving → processing → shipping.

This ensures that parts and people do not intersect and that large trucks can move in a one-way direction to ensure safety.

| Factory Case Studies | Pressing, Forging, Machining, Plastic Molding, Rubber, Aluminum Die Casting, etc. | Product Assembly, Home Appliance Assembly, etc. |

| Block Layout |

|

|

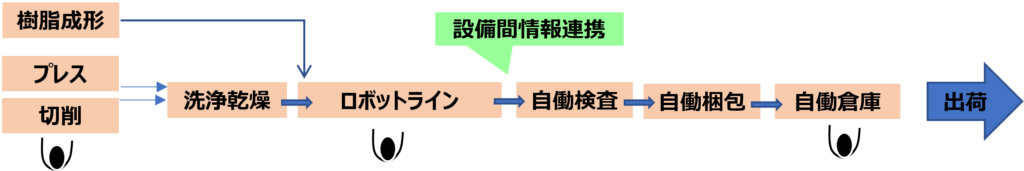

Gain Competitiveness through Equipment Development

One of the challenges faced during the factory setup is deciding on the equipment.

Using catalog equipment for production won’t differentiate you from competitors. It is crucial to strengthen competitiveness by designing unique equipment aimed at high targets.

Compared to combining off-the-shelf equipment, developing your own equipment takes significantly more time to consider functionality, test machines, and productivity. However, by clearly defining the ‘concept and goals’ and leveraging the know-how and experience gained from promoting equipment development, you will be able to build your own production lines after the project’s completion.