Designing a Future-Ready Factory Layout

to Outperform the Competition

結果

Introducing a Case Study on New Factory Launch Consulting

When it comes to general new factory launch services, the following tendencies are often observed:

In contrast, our new factory launch consulting uniquely integrates both perspectives: We specialize in developing factory layouts based on on-site process improvement while also considering the overall building concept. This holistic approach ensures a truly optimized and future-ready factory environment.

- Industry details

- Precision equipment manufacturer

- Country

- Japan

- Company size

- 500 Employees

- Assignment

- Improved productivity

- Purpose

- 生産性 向上

- Industry

- 電機・電子

Key Strengths of Hirayama Consulting

Balancing Layout Planning Based on Shop Floor Improvements and Building Concept DevelopmentAssessment of Current Processes and Identification of Improvement Areas

(1) Identifying Bottleneck Processes

Carrying over the waste and issues of an existing factory into a new one only leads to inefficiencies—such as increased construction costs due to unnecessarily large floor space—with no real benefits. That’s why we begin by conducting a thorough investigation of current manufacturing operations to determine what must be addressed in order to minimize waste and resolve existing issues.

By taking a bird’s-eye view of the entire production line, we identified:

(2)Equipment Consolidation Planning

One essential element in the basic design of a new factory is the Equipment Utility List, which summarizes key information for each machine—such as dimensions (height/width/depth), weight, and power requirements. At Hirayama Consulting, we also include operating time data for each piece of equipment.

Many clients operate multiple machines for the same function, often using them exclusively by product type. However, this lowers the utilization rate per unit, reducing overall efficiency. Based on our findings, we recommend:

As a general benchmark, equipment with monthly operating time of less than 50 hours (i.e., less than 25% utilization) is considered a candidate for consolidation. (3)Introducing AGVs

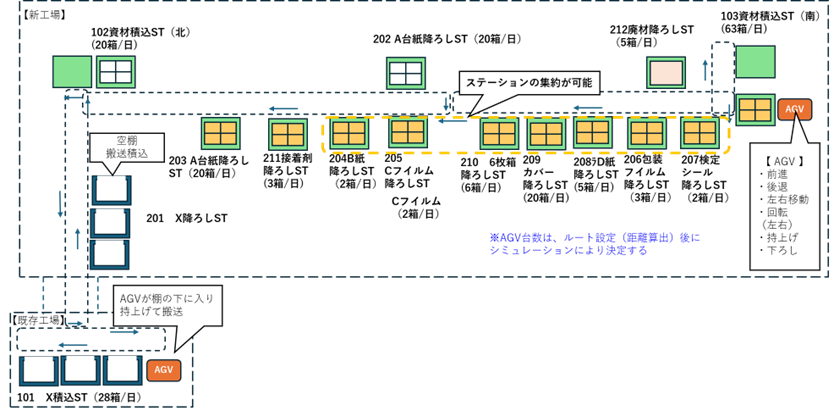

In the current factory, materials and work-in-progress items were primarily transported manually. In our new layout proposal, we introduced Automated Guided Vehicles (AGVs) to streamline logistics.

The adoption of AGVs allowed for the automation of transport between the existing and new factories, reducing manual handling and significantly improving production efficiency. As a result, we were able to lower both workload and overall costs.

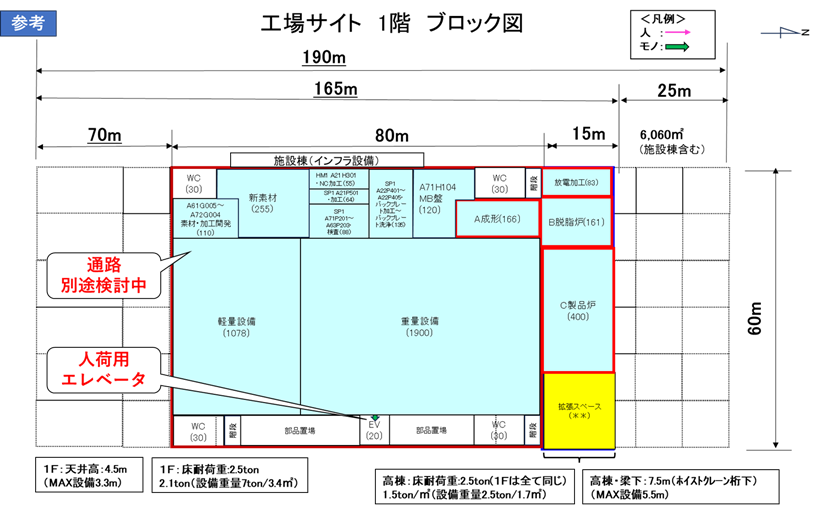

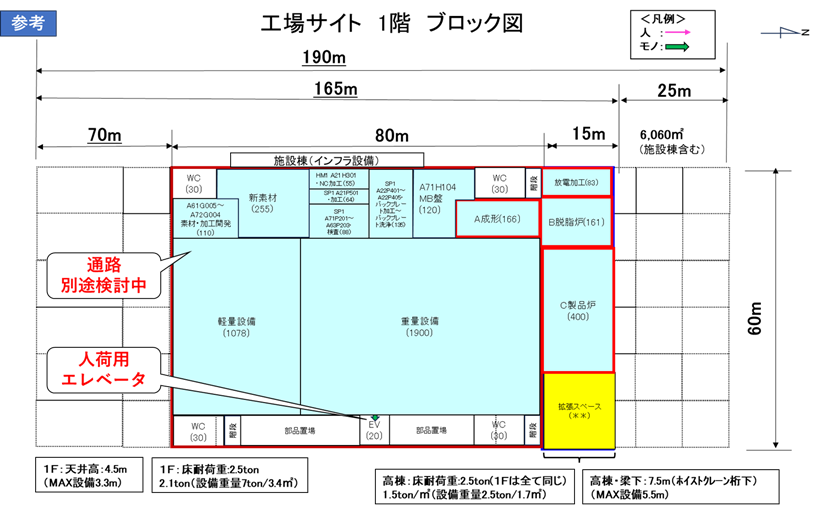

Creating a Process Block Layout

After calculating the required total floor area, we developed the process block layout through in-depth discussions with the client to ensure both functionality and efficiency.

(1)Streamlining Workflows

We focused on minimizing the movement paths for both materials and personnel to enhance overall operational efficiency.

(2)Layout Planning Beyond Production Processes

In addition to production areas, we also planned for non-production spaces such as:

Specialist in Manufacturing Support

Tomohiro Suzuki

Former employee of Japan Tobacco Inc., Technical Development Department, Manufacturing Department

With many years of experience in production engineering development and manufacturing site management, he has led initiatives in new process development, safety management, quality improvement, cost reduction, delivery control, and workforce training—especially on the factory floor. He excels at supporting various problem-solving efforts and managing project progress in close collaboration with clients.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

3 reasons why we are chosen REASON

REASON 1

Improvement experience of

more than 1,500 companies in 40 countries

There must be the shop floor issues that cannot be solved by your own company alone. Improvements and reforms for manufacturing industry to survive, regardless of country or industry, need development of your human resources through practical experiences of improvement, and strengthening of your production system base.

REASON 2

Consulting that shop floor workers

acknowledge our superiority and be pleased

In conventional consulting styles, there was a distance between consultant and the shop floor because it was promoted mainly consultant and management executives. Our consultant can provide a guidance without a distance between consultant and the shop floor through the guidance based on the “seeds of improvement” in a concrete way, instead of “finding fault” like a critic.

REASON 3

Continuous improvement will continue

even after the end of guidance

While strengthening “human resource development”, we focus on the “overall flow” from design to purchasing, manufacturing, logistics, and production control, and provide guidance that matches the actual situation of your company. Continuous improvement will continue even after the end of guidance through the guidance that is acceptable to the shop floor workers.