It’s common to hear such feedback from seminar participants and others.

How about your company?

It’s important to convey your strong beliefs to your employees in your own words.

“I’ll share the words of a 38-year-old female general manager from a certain furniture manufacturer in China, spoken at the kickoff meeting for improvement activities.“Six months ago, I attended a seminar in Japan, and I have decided to invite the instructor from that seminar to our company starting this month.

We will hold a seminar once a month.

To make it easier for everyone to attend, we will conduct these sessions as overtime work.

Our company has been operational for less than five years.

Some of you may be considering changing jobs soon.

As your president, I’m okay with that.

We will prepare late-night snacks and pay overtime allowances.

Please make sure to attend the instructor’s seminars.

>

Even if you end up changing jobs after listening to the instructor from Japan, I am confident that what you learn will undoubtedly be beneficial in your new endeavors.”

1. Let the president lead by example.

This is a common point not just in any specific country but across all enterprises worldwide.br>

It’s crucial not just for the president to provide funding but also to take the lead personally, to step onto the shop floor, and to show genuine interest in understanding the operations closely.

Let’s incorporate the president’s participation in the activities into the annual schedule in advance to ensure their attendance at every session.

2. First, let’s start with praise.

In front of everyone, express your gratitude by saying “Well done” and praise them sincerely. Everyone feels more motivated when they are praised. It’s good to give some instructions or homework after praising.

The strategy is to “motivate people by praising them.

3. Let’s think together as a team.

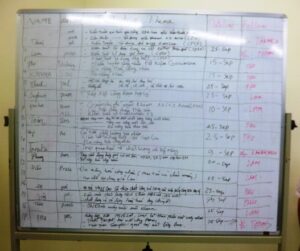

Conduct site observations (waste hunting) and have everyone present the waste they’ve found. Then, set deadlines and responsible persons to formulate an action plan. Once improvements are made and work becomes easier, improvement activities will become enjoyable and take hold.

Having waste is not so much the problem. The most troublesome issue for a company is when no one realizes the waste piling up at the site.

I always request, “Please do not scold for failures that come from trying.”

Scolding discourages further attempts. Investigating the causes of failures and guiding to prevent repetition leads to personnel development.

Isn’t it true that everyone learns and grows from their failures?

“Manufacturing starts with people making.”

4. Moving Away from Finding Reasons Why Something Can’t Be Done

This is a common trait among companies that fail to achieve results.

When faced with improvement proposals, the first responses are often reasons why it can’t be done or why they don’t want to do it.

This tendency is particularly prevalent among very experienced employees.

It might stem from pride in the systems they’ve built, but it prevents improvement from progressing.

As a result, younger employees become hesitant to speak up.

5. Let’s increase our options!

There are virtually no opportunities for interaction with other companies, or if there are, they are limited to activities like golf, leading to a situation where one becomes a “frog in a well,” with a narrow perspective.

Let’s continue to accumulate classroom learning and factory tours to progressively expand our range of options.

Let’s make the most of your expertise!

The companies I’ve assisted with improvement activities span a variety of industries, including palm oil plantations, security cameras, beverage cartons, plastics, furniture, and watch parts manufacturers.

A common question I encounter during factory diagnostics visits is, “Do you have expertise in this industry?”

I believe there’s no need to worry, as you all possess the necessary specialized knowledge.

The consultant who wrote this column

ORITO, Tsutomu

Toyota Motor Corporation

Profit improvements (break away from the deficit) Upon customer’s requests, I have improved domestic and overseas companies, for examples, productivity improvement, quality improvement, products and parts inventory reduction, logistics cost reduction, production lead time reduction, and human resource development for shop floor staff etc. I also conducted a wide range of seminar courses.

3 reasons why we are chosen REASON

REASON 1

Improvement experience of

more than 1,500 companies in 40 countries

There must be the shop floor issues that cannot be solved by your own company alone. Improvements and reforms for manufacturing industry to survive, regardless of country or industry, need development of your human resources through practical experiences of improvement, and strengthening of your production system base.

REASON 2

Consulting that shop floor workers

acknowledge our superiority and be pleased

In conventional consulting styles, there was a distance between consultant and the shop floor because it was promoted mainly consultant and management executives. Our consultant can provide a guidance without a distance between consultant and the shop floor through the guidance based on the “seeds of improvement” in a concrete way, instead of “finding fault” like a critic.

REASON 3

Continuous improvement will continue

even after the end of guidance

While strengthening “human resource development”, we focus on the “overall flow” from design to purchasing, manufacturing, logistics, and production control, and provide guidance that matches the actual situation of your company. Continuous improvement will continue even after the end of guidance through the guidance that is acceptable to the shop floor workers.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays