Would you like to try a factory diagnosis to solve your challenges?

Factory diagnosis refers toa process of understanding the current state of your factory, identifying problems, and proposing strategies and approaches for improvement.

Currently, companies are facing challenges that must be overcome, such as the issue of declining birthrates, currency depreciation, and the realization of a sustainable world on a global scale. To prevail in the intensifying competition, it is essential to calmly assess the current situation and immediately start addressing these challenges. By conducting a factory diagnosis to objectively identify what problems exist on the shop floor, superficial improvements can be eliminated, allowing for the acquisition of competitive strength by overcoming weaknesses.

- Objective perspective through a professional’s eye

- Proposals that integrate on-site improvement measures with employee awareness enhancement

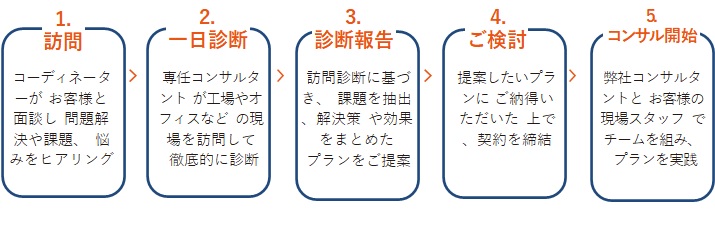

Consulting Flow

While there may be slight variations depending on individual cases, the basic steps are as follows before transitioning to actual consulting. If you have any questions, please feel free to ask our consultants.

Factory diagnosis daily schedule

You will be asked to submit materials such as factory layout diagrams and documents showing production progress in advance, but there is no need to prepare anything new. We will proceed with what is currently available.

| 09:00 | <Arrived at the factory>

<Preliminary Meeting>※Please explain the following (Problems related to quality, productivity, procurement, production volume, inventory management, production technology, etc.) |

conference room |

| 09:30-15:00 | <Factory Diagnosis> |

Shop Floor |

| 15:00-15:30 | <Summary of the Factory Diagnosis> | conference room |

| 15:30 | <Preliminary Diagnostic Report> | conference room |

| 16:00 | end |