A reform on which the company’s fate depends

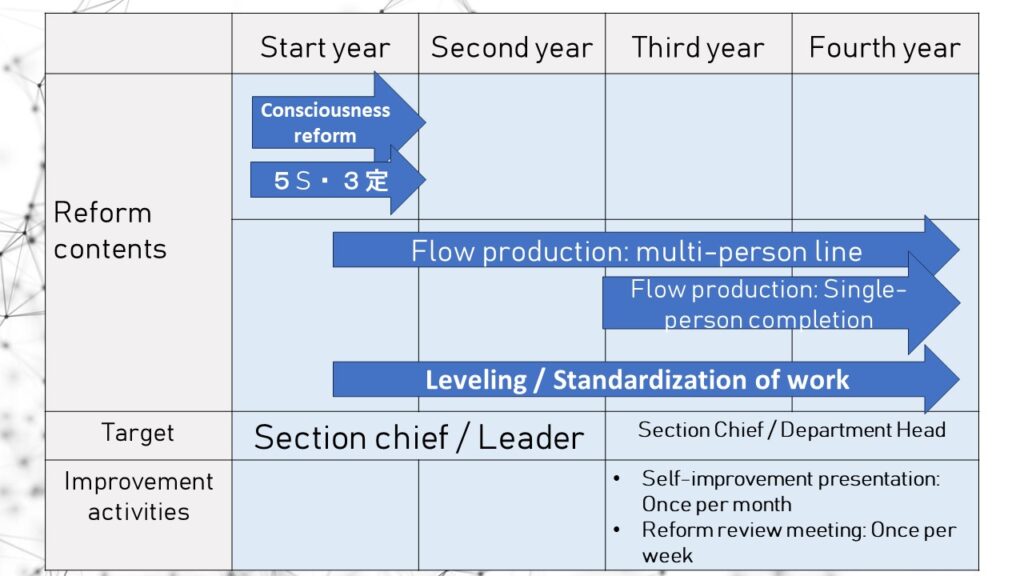

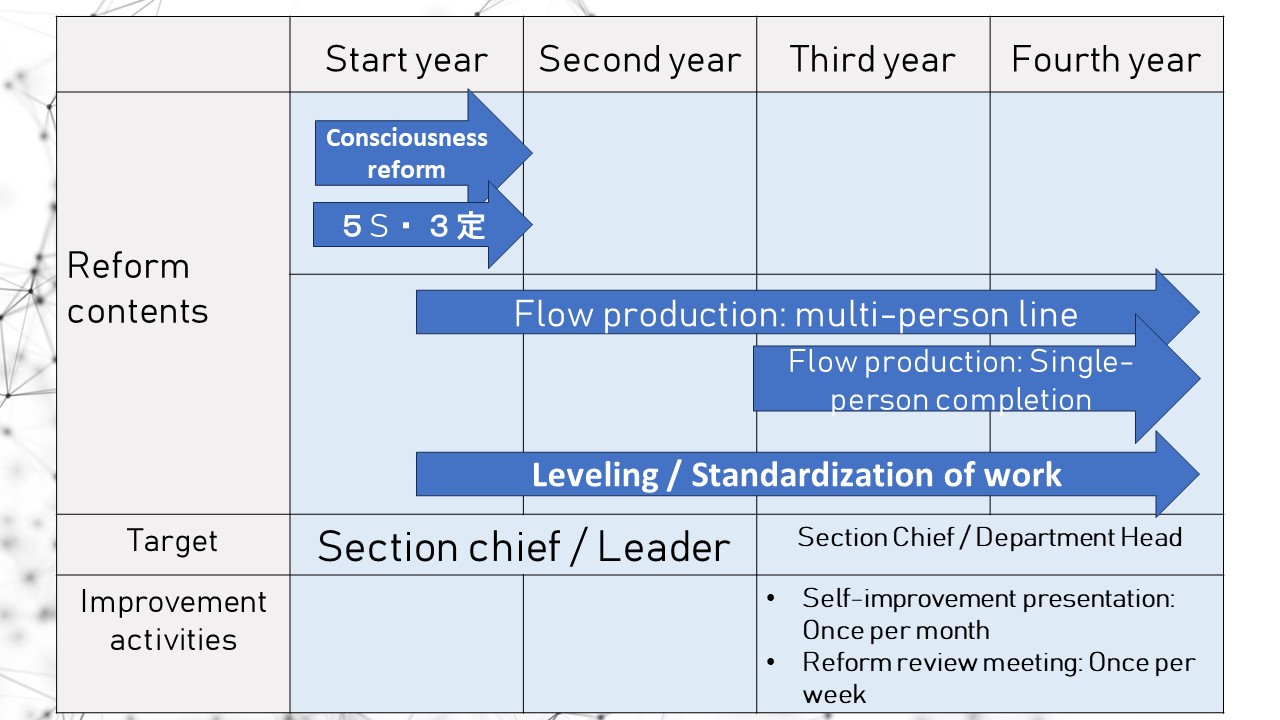

A four-year project

Result

Defect rate: Less than 0.1%

Lead time 16-hour reduction

On-time delivery rate of 98%

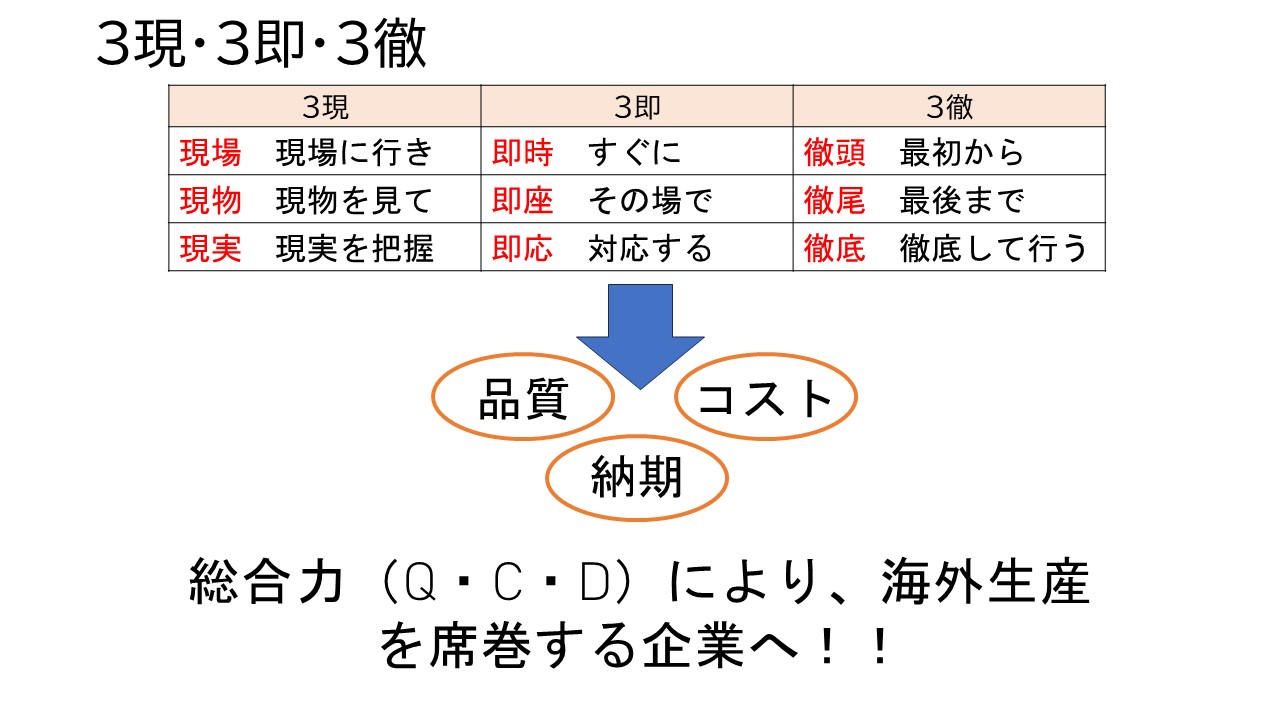

To survive against foreign products, it was necessary to reduce costs and shift towards a system capable of handling a wide variety of products in small quantities.

The field resists change, but over the course of about a year, worker education (awareness reform) was conducted, and the reform was implemented. The number of improvements per person ranged from 5 to 15 items per month.

During the four-year project, more than 40,000 improvements were made, achieving targets in productivity, defect rate, on-time delivery rate, and lead time for each item.

- Industry Details

- Precision Machinery

- Country

- Japan

- Company Size

- Employees: 100 to 200

- Challenge

- High-mix, low-volume production

- Objective

- Profitability improvement

- Industry

- Electrical and electronic

The background of the reform

| Industry trends |

|

| Current situation |

|

| Issues |

|