On-time delivery in a factory means meeting the delivery deadlines promised with the customer.

Maintaining a trusting relationship with the customer is essential for the prosperity of a company, so we must absolutely meet the delivery deadlines.

Solve these issues

with on-time delivery in a factory

ISSUE

3 points

for on-time delivery

FEATURES

-

1

Realization of cost reduction

-

The prerequisite is to meet the delivery deadlines while realizing cost reduction.

-

2

Stable quality

-

It does not mean that “defective products may be provided to meet the delivery deadlines”. Stability of quality is an important factor of meeting the delivery deadlines.

-

3

Just-in-time

-

To meet the delivery deadlines without having an extra inventory, it is necessary for each process to manufacture just in time.

Realization of cost reduction

Meeting the delivery deadlines while reducing costs is a matter of course that any company must do.

In the manufacturing industry, it is extremely important to meet the delivery deadlines and deliver speedy and accurately. For that purpose, it is essential that manufacturing department cooperates with sales, management, and purchasing departments, and also communicates with cooperating companies.

Smoothing the “flow of information and materials” of related departments and cooperating companies will lead to on-time delivery and eventually reduce costs.

Stable quality

Delivery deadlines and quality are completely different matters, and it is not a matter of thinking which should be prioritized.

It is a matter of course for the manufacturing industry to produce 100% non-defective products, and there is an obligation to deliver 100% non-defective products to customers on time.

In order to do so, it is necessary to proceed with production activities based on the concept of “following process is your customer” and “making quality in the process”.

Just-in-time

If you meet the customer’s delivery deadlines with a lot of inventory, it will lead to higher costs.

It is important for each process to manufacture without stagnation based on the idea of Just-in-time, “what you need, when you need it, as much as necessary”.

Just-in-time enables us to quickly respond to diversified customer needs and reduce inventory costs. It is also effective in the distribution industry such as supermarket.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

On-time delivery Specialist

HAYASHIDA, Hiromitsu

Toyota Motor Corporation, Horie Metal Co., Ltd.

A TPS specialist. His expertise lies with welding and assembly technology. He promotes Kaizen (continuous improvement) that comprehensively encompasses entire factory operations including procurement and production control. He is well-versed in giving advice to different types of factories and plants.

Case example of Genba Kaizen Consulting RESULTS

Acquired orders from two new customers

by improving quality.

We reduced most work-in-progress inventories and defective inventories, which were found throughout the factory, and reduced manpower, and now we almost no longer receive customer complaints that we had every month before. (Automobile industry / Plant manager)

Turn the factory into a showroom

in order to improve profitability

We improved 250 cases out of 300 cases pointed out by the 5S patrol conducted for one year. The factory was realized to be the showroom and also achieved cost reduction of 30 million yen per year. (Metal processing / Director)

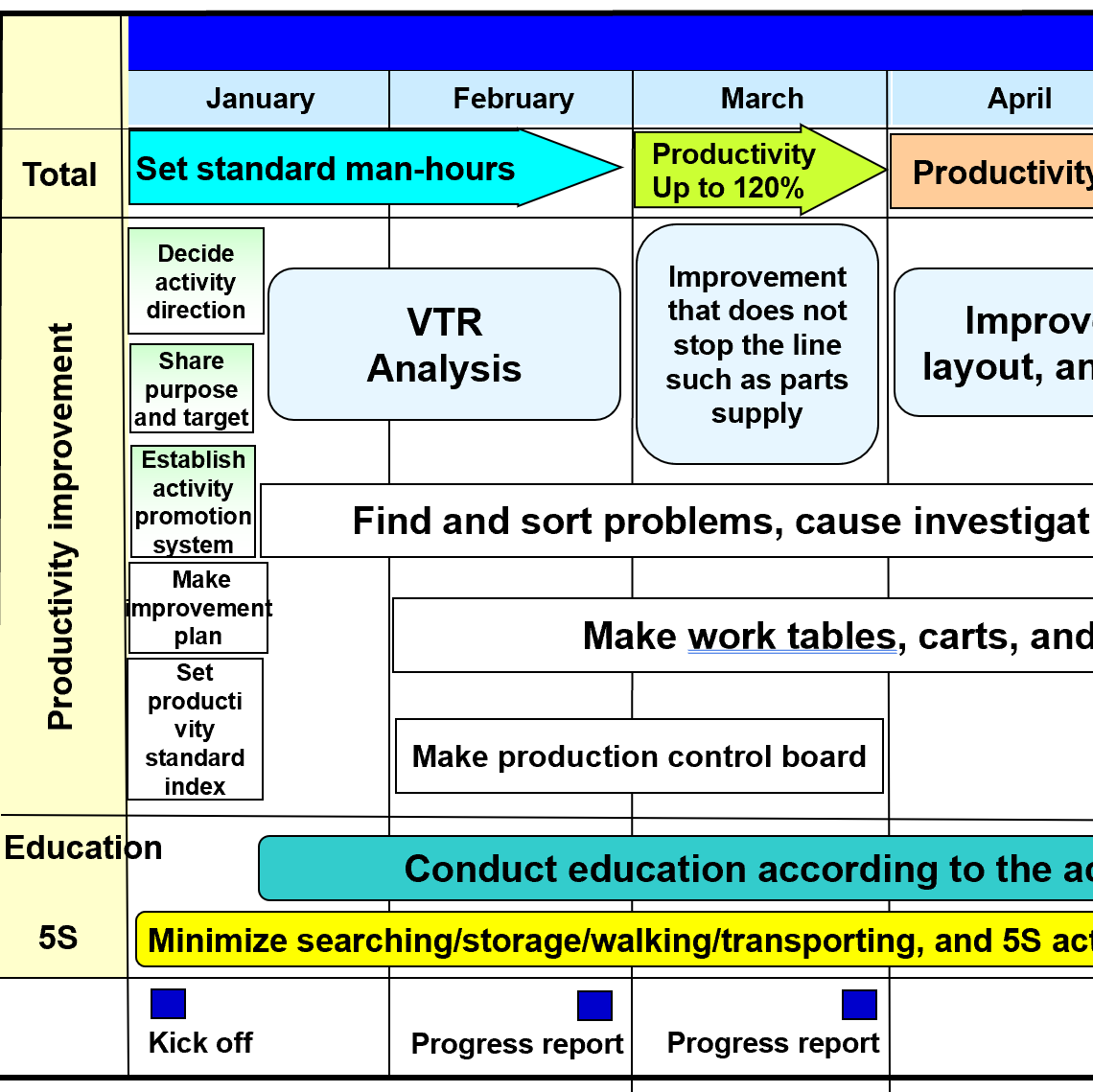

Productivity Up to 169.6%

by 6 months of improvement activities

the Japanese president decided to outsource a shop floor improvement consulting to have their shop floor checked, and asked us, Hirayama Consulting.(Auto parts manufacturer/Managing director)

3 reasons why we are chosen REASON

REASON 1

Improvement experience of

more than 1,500 companies in 40 countries

There must be the shop floor issues that cannot be solved by your own company alone. Improvements and reforms for manufacturing industry to survive, regardless of country or industry, need development of your human resources through practical experiences of improvement, and strengthening of your production system base.

REASON 2

Consulting that shop floor workers

acknowledge our superiority and be pleased

In conventional consulting styles, there was a distance between consultant and the shop floor because it was promoted mainly consultant and management executives. Our consultant can provide a guidance without a distance between consultant and the shop floor through the guidance based on the "seeds of improvement" in a concrete way, instead of "finding fault" like a critic.

REASON 3

Continuous improvement will continue

even after the end of guidance

While strengthening "human resource development", we focus on the "overall flow" from design to purchasing, manufacturing, logistics, and production control, and provide guidance that matches the actual situation of your company. Continuous improvement will continue even after the end of guidance through the guidance that is acceptable to the shop floor workers.