On-Site Improvement : 40,000 Cases in 4 Years

[Results]Productivity 26%UP

Defect rate: Less than 0.1%

Lead time 16-hour reduction

On-time delivery rate of 98%

[Purpose]

Profitability improvement

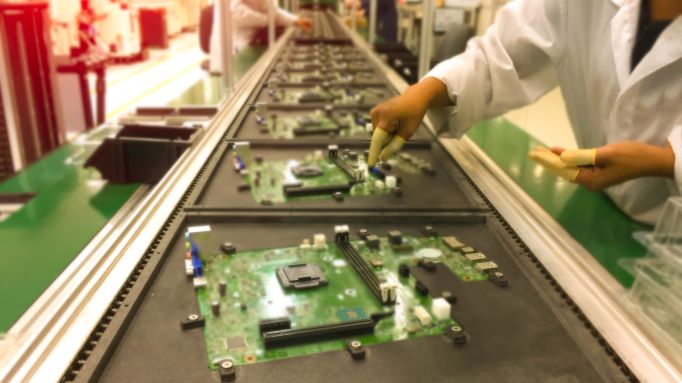

Electrical and electronic

[Online Consulting Case Study] 30% Productivity Increase in One Year

[Results]Improvement of Setup Change Operations

(Before Improvement)92 minutes 34 seconds→(After Improvement)53 minutes 2 seconds (reduced by 39 minutes 32 seconds)

[Purpose]

Profitability improvement

Others

Immediate Improvement Examples in a Food Factory

[Results]From 277 pieces per hour → 450 pieces per hour

Productivity Increase by 62%

[Purpose]

Profitability improvement

food

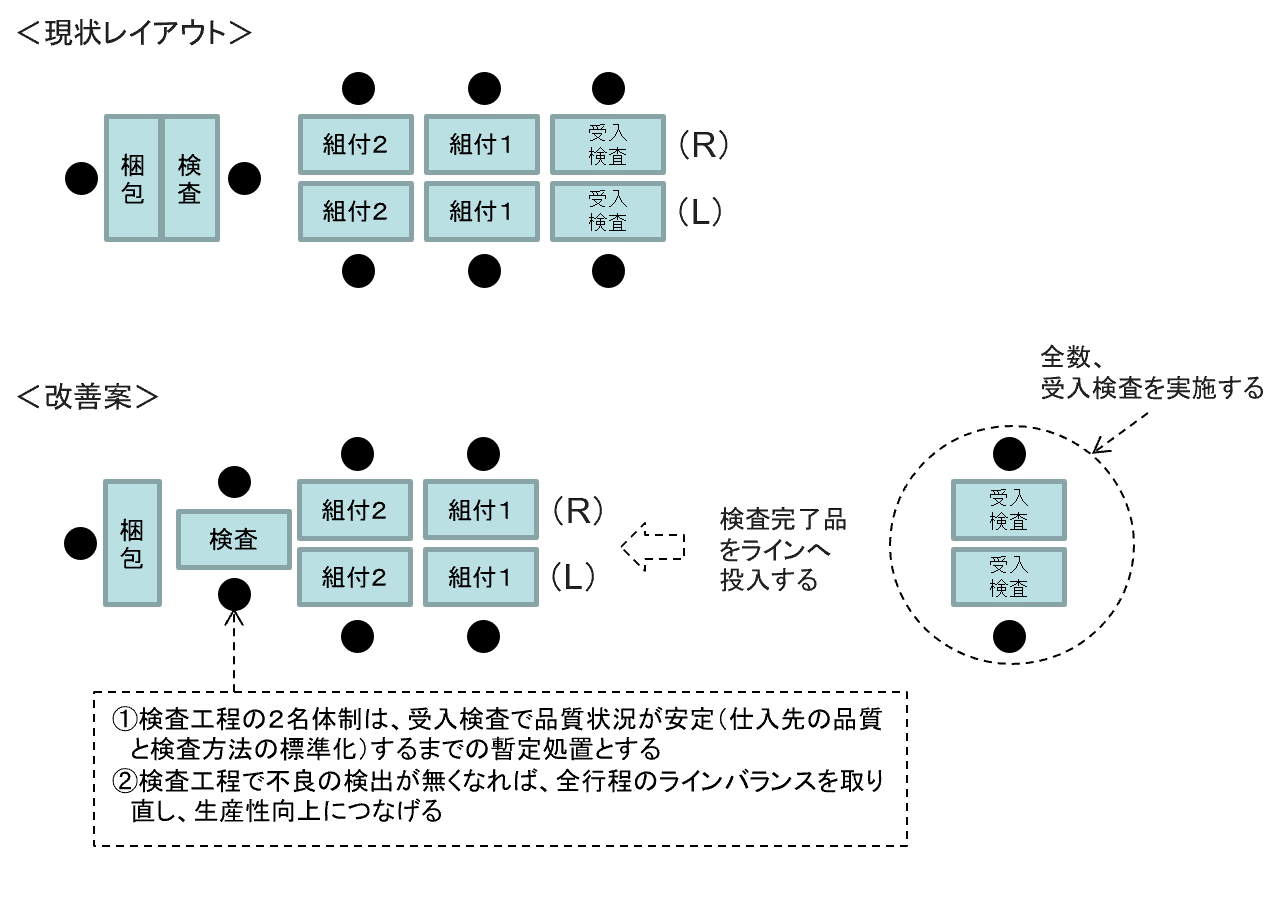

Case example of factory diagnosis (Simple type)

[Results]- Issues that customers could not see or notice can be identified

- Improvement plan that combines measures for the shop floor improvement and employees’ awareness improvement

[Purpose]

Human resource developmentProfitability improvement

Automobile

Kaizen (improvement) Case Study in Production Control

[Results]・Making manufacturing variation to Heijunka (level out), which enabled to shorten lead-time from 2 days to 120 minutes

・Achieving Zero Inventory

[Purpose]

Profitability improvement

Electrical and electronic

How to do KAIZEN: tips for food manufacturing factories

[Results]<Setup time Reduction>

Before KAIZEN 10 min. → After KAIZEN 5min.

[Purpose]

Profitability improvement

food

IOT Kaizen Digitization of Analog Meters

[Results]・The time required for meter monitoring and data entry work was reduced from 15 hours/month (360 Kyen/year) to 0 hours/month

・Abnormal condition is reported in real time on smartphone. So, quick action is possible.

[Purpose]

Quality improvementProfitability improvement

food

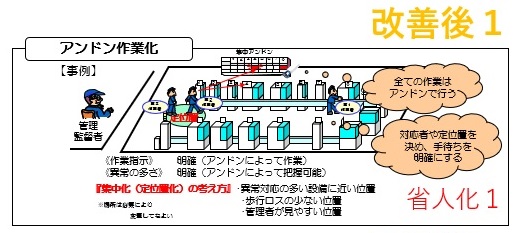

Autonomation (JIDOKA) improvement in electrical device manufacturing

[Results][Purpose]

Profitability improvement

Electrical and electronic

Remote Gemba (on site)KAIZEN: KAIZEN without entering a factory

[Results]Before KAIZEN Total Cycle Time 940”

⇓

After KAIZEN Total Cycle Time 700” Production Volume 30% increase

[Purpose]

Profitability improvement

Metal

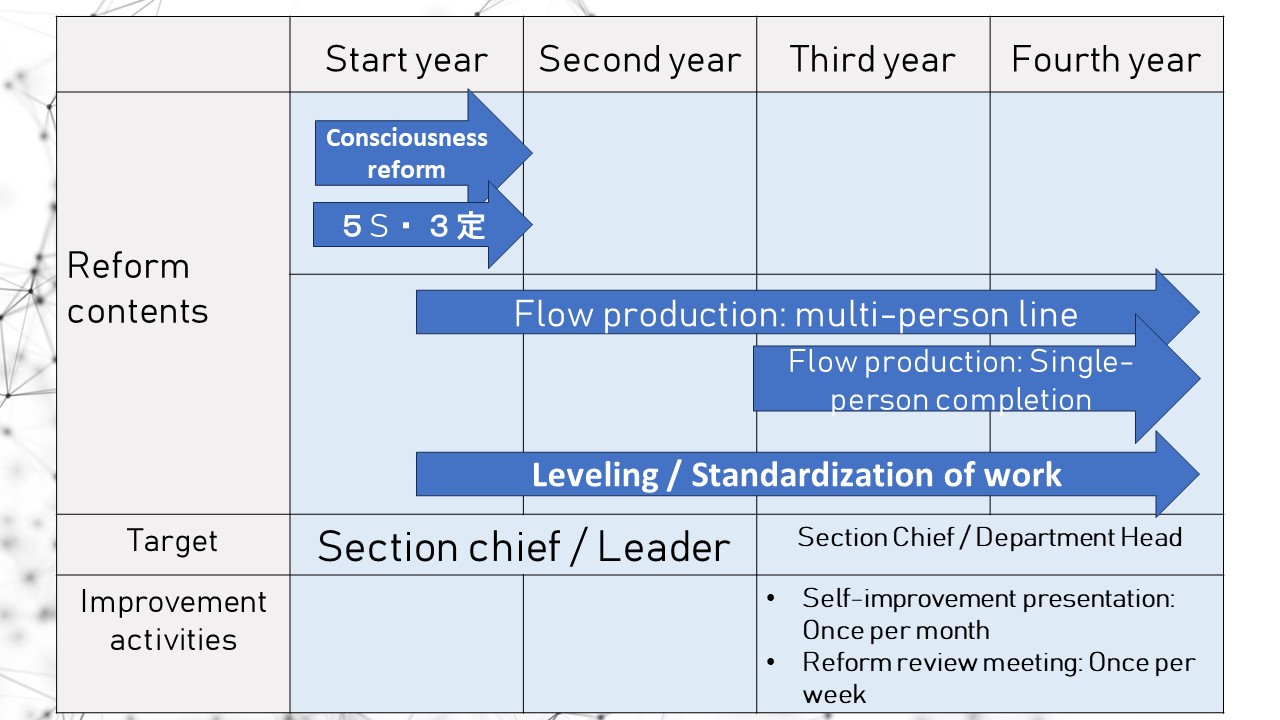

Make a deficit factory overseas profitable

[Results]- Turn profitable two years after the start of improvement activities.

- Acquired orders from two major new customers by improving quality.

[Purpose]

Quality improvement5sProfitability improvement

Others

3 reasons why we are chosen

REASON

REASON 1

Improvement experience of

more than 1,500 companies in 40 countries

There must be the shop floor issues that cannot be solved by your own company alone. Improvements and reforms for manufacturing industry to survive, regardless of country or industry, need development of your human resources through practical experiences of improvement, and strengthening of your production system base.

REASON 2

Consulting that shop floor workers

acknowledge our superiority and be pleased

In conventional consulting styles, there was a distance between consultant and the shop floor because it was promoted mainly consultant and management executives. Our consultant can provide a guidance without a distance between consultant and the shop floor through the guidance based on the “seeds of improvement” in a concrete way, instead of “finding fault” like a critic.

REASON 3

Continuous improvement will continue

even after the end of guidance

While strengthening “human resource development”, we focus on the “overall flow” from design to purchasing, manufacturing, logistics, and production control, and provide guidance that matches the actual situation of your company. Continuous improvement will continue even after the end of guidance through the guidance that is acceptable to the shop floor workers.

Consultants from major companies

with experience in over 40 countries will respond.

Please feel free to contact us.

If you are in a hurry, please call us.

(Japan time)

Open 08:30 – 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays